how to set up a tracker for fuel monitoring

Setting up a tracker for fuel monitoring involves both hardware installation and software setup. Here’s a step-by-step guide:

1. Choose the Right Fuel Tracking System

- Hardware: Decide on the type of fuel tracking hardware you need. Options include:

- OBD (On-Board Diagnostics) Devices: Plug directly into the vehicle’s OBD-II port.

- Fuel Sensors: Installed in the fuel tank to measure fuel levels directly.

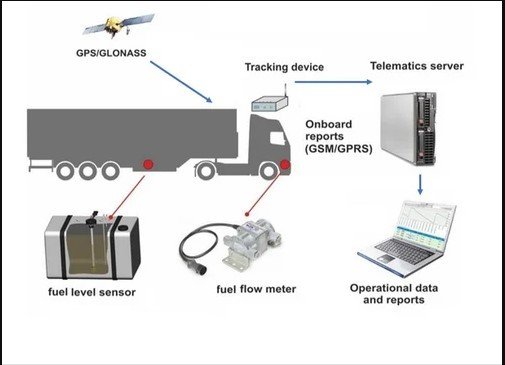

- Telematics Devices: Offer GPS tracking along with fuel monitoring.

- Software: Choose a compatible software platform that supports fuel tracking. Many GPS tracking platforms have built-in fuel monitoring features.

2. Install the Hardware

- OBD Device:

- Locate the OBD-II port (usually under the dashboard near the steering wheel).

- Plug the device into the port. This requires no tools and is easily removable.

- Fuel Sensors:

- Install the sensor directly into the fuel tank. This might require drilling and should be done by a professional to avoid damaging the tank.

- Telematics Devices:

- Install the device in the vehicle. Connect it to the vehicle’s power supply and fuel gauge wire.

- Some devices might also require GPS antenna installation for location tracking.

3. Configure the Software

- Platform Setup:

- Log into the chosen tracking software.

- Register your devices by entering serial numbers or using QR codes.

- Calibration:

- Calibrate the system to ensure accurate fuel readings. This might involve filling the tank and entering specific fuel levels into the software.

- Set up alerts for refueling, fuel theft, or abnormal fuel consumption.

- Integration:

- If you’re using fleet management software, integrate fuel data with other tracking data (e.g., GPS, mileage).

4. Monitor and Analyze

- Real-Time Monitoring:

- Use the software dashboard to monitor fuel levels in real-time.

- Set up notifications for critical alerts, such as sudden drops in fuel levels.

- Reporting:

- Generate reports to analyze fuel consumption over time.

- Identify trends, such as fuel efficiency or theft, and adjust operations accordingly.

5. Maintenance

- Regularly check the hardware for any issues.

- Update software as necessary to ensure compatibility and security.

- Recalibrate sensors periodically to maintain accuracy.

By following these steps, you’ll be able to effectively monitor fuel usage, reduce costs, and prevent fuel-related issues in your fleet or personal vehicles.

Certainly! Here’s a deeper dive into the process of setting up and optimizing a fuel monitoring system:

1. Detailed Hardware Selection

- Types of Fuel Sensors:

- Capacitive Sensors: Measure fuel level based on the capacitance of the fuel in the tank. They are highly accurate but require professional installation.

- Ultrasonic Sensors: Use sound waves to measure the fuel level. They can be installed without drilling but may not be as accurate as capacitive sensors.

- Float Sensors: A mechanical device that floats on the fuel surface and measures the level as it rises and falls. These are less sophisticated but can be adequate for basic monitoring.

- Telematics Devices:

- GPS with Fuel Monitoring: Some GPS devices come with integrated fuel monitoring, allowing you to track both location and fuel data simultaneously.

- CAN Bus Integration: For more advanced tracking, devices that integrate with the CAN bus of the vehicle can provide real-time data on fuel consumption directly from the vehicle’s engine control unit (ECU).

2. Advanced Installation Techniques

- Installation Tips for Fuel Sensors:

- Tank Positioning: Ensure the sensor is installed in a central and stable position to avoid false readings due to fuel sloshing.

- Sealing: Properly seal any drilled holes to prevent fuel leaks and maintain the integrity of the tank.

- Wiring: Route wires away from high-heat areas and moving parts. Use protective casing or conduit to prevent damage.

- OBD-II Device Installation:

- If using an OBD-II device, ensure it’s properly seated in the port to avoid disconnection due to vibrations. Consider using a locking OBD-II connector for a more secure installation.

3. Advanced Software Configuration

- Calibration Techniques:

- Partial Calibration: Fill the tank partially and log the amount in the software to create a calibration curve. Repeat this at multiple levels to increase accuracy.

- Temperature Compensation: Configure the software to account for temperature changes, which can affect fuel density and sensor readings.

- Custom Alerts:

- Set up geofencing alerts to notify you if the vehicle refuels outside of approved locations.

- Configure theft alerts for sudden, unapproved fuel level drops.

- Driver Behavior Integration:

- Link fuel consumption data with driver behavior analysis. For example, identify patterns of aggressive driving (like rapid acceleration) that lead to higher fuel consumption.

- Fuel Cost Tracking:

- Input fuel prices into the system to track costs. Some systems allow for real-time fuel price integration to optimize refueling locations.

4. Integration with Other Systems

- Fleet Management Software:

- If you manage a fleet, integrate fuel monitoring with fleet management software. This can automate maintenance scheduling based on fuel consumption and other vehicle data.

- Accounting Software:

- Integrate with accounting systems to automatically generate fuel expenditure reports, simplifying financial tracking and budgeting.

5. Optimization and Analysis

- Data Analysis:

- Regularly analyze fuel data to identify trends such as fuel consumption per route, seasonal variations, or differences between vehicles.

- Use historical data to predict future fuel needs and budget accordingly.

- Route Optimization:

- Combine fuel data with GPS tracking to optimize routes for fuel efficiency. Identify routes with heavy traffic or frequent stops that lead to higher fuel consumption.

- Preventative Maintenance:

- Monitor fuel consumption for sudden increases, which might indicate engine problems or fuel leaks. Use this data to perform preventative maintenance before issues become costly.

6. Ongoing Maintenance and Updates

- Hardware Maintenance:

- Periodically inspect sensors and telematics devices to ensure they are functioning properly. Look for signs of wear, corrosion, or damage.

- Software Updates:

- Keep software up-to-date to benefit from new features, bug fixes, and security patches.

- Recalibration:

- Recalibrate sensors after any major vehicle maintenance, such as fuel tank repairs, to maintain accuracy.

7. Legal and Compliance Considerations

- Regulatory Compliance:

- Ensure your fuel monitoring system complies with local regulations, especially if monitoring a fleet. This might include data privacy laws or specific requirements for commercial vehicles.

- Data Security:

- Protect the data collected by your fuel monitoring system. Use encryption and secure access controls to prevent unauthorized access to sensitive information.

By delving into these advanced aspects, you can create a highly effective and efficient fuel monitoring system tailored to your specific needs. This can lead to significant cost savings, improved operational efficiency, and better overall management of your vehicles or fleet.